one of the largest

injection moulding companies of the Netherlands

Lolaar Spuitgiettechniek BV is a plastic injection moulding company in Helmond, founded by Antoon and Francien Loverbos in 1982.

Thanks to many learning processes over the years (with of course regular falls and always getting up again), we have grown into a beautiful, growing, thriving company with an extensive and highly automated, hi-tech machine park.

Quality, continuity, price-performance ratio, delivery reliability and innovation are the pillars of our company. A ‘no nonsense’ culture has always been the guiding principle.

Partly because of this, the name ‘Loverbos / Lolaar’ is a household name in the global plastic injection moulding world.

With our knowledge and expertise, we make the difference and, with a business area of 35,000 m2, we are now one of the largest injection moulding companies in the Netherlands.

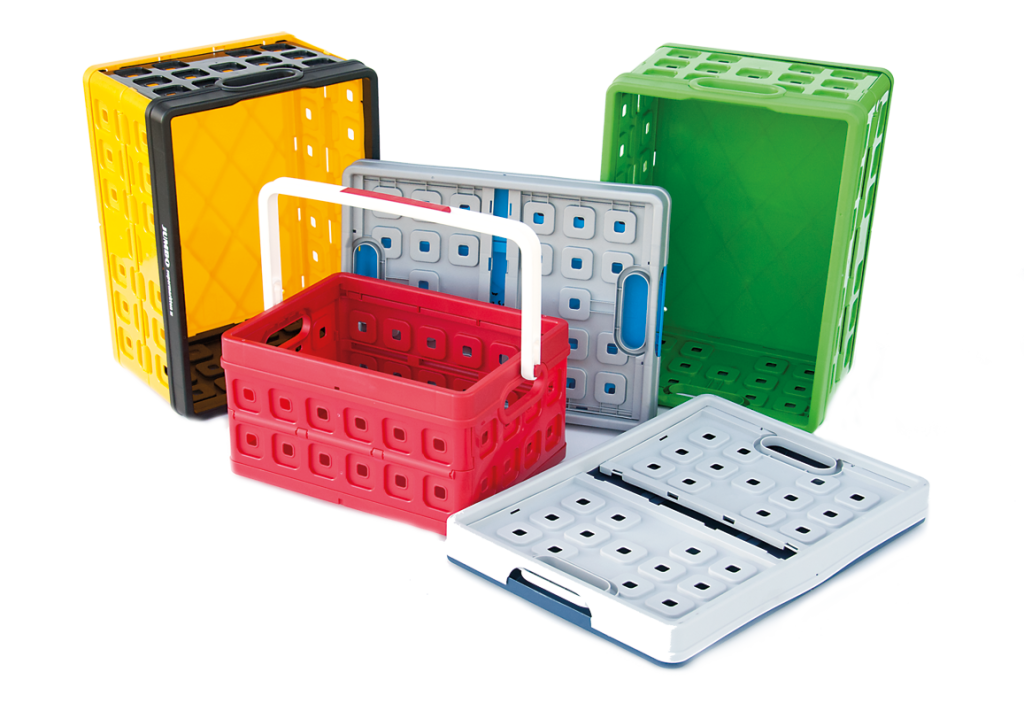

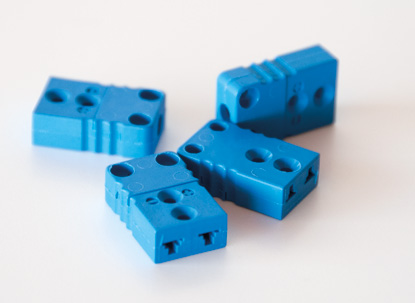

Our core business is developing, manufacturing and shipping fully recyclable thermoplastic parts. We do this in a controlled, closed production process, using a fully automatic raw material supply system.

Moreover, our production process is set up in such a way that almost all residual product / production waste can be reprocessed internally into new product. In short, an economic, clean and environmentally conscious process execution!

Our main markets are the automotive industry, electronics companies, machine and equipment manufacturers, the packaging industry and horticulture. In recent years, we have grown to become the all-round specialist in injection moulded products.

We will gladly take up a challenge with you; at Lolaar Spuitgiettechniek BV a lot is possible!

If, further to this website, you have any questions or are otherwise interested, we invite you to contact us!